Challenge from industrial production

With conventional mechanical clamping devices, vibrations often lead to poorer surface quality of the workpiece, high tool wear, high noise levels and high manufacturing tolerances. In many manufacturing companies, process feed rates are often simply reduced in order to keep the machining forces low and thus minimize vibrations. However, this slows down the production process considerably, which results in a significant increase in tool costs, machine hours and thus the manufacturing costs of the component.

Solution path in the research project

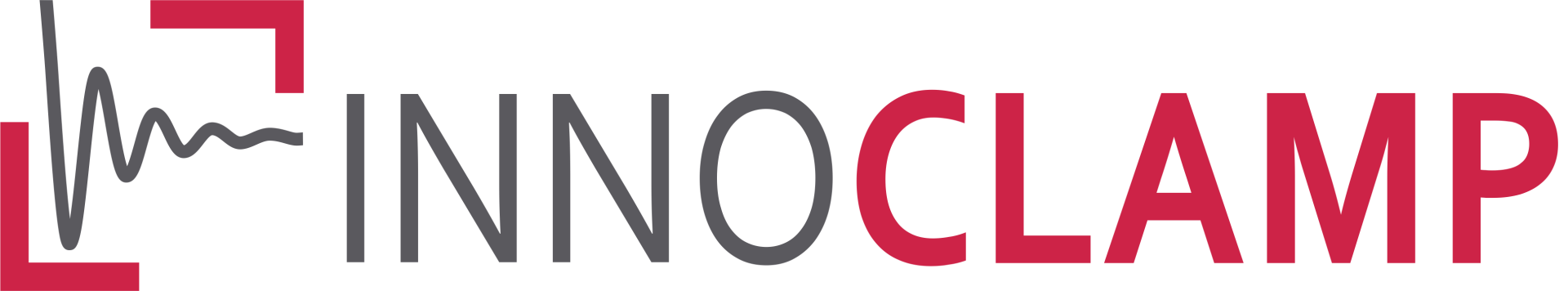

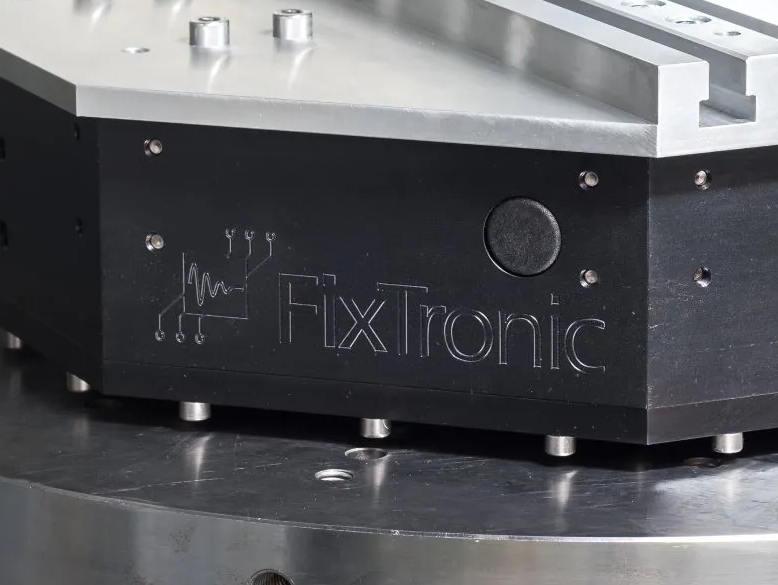

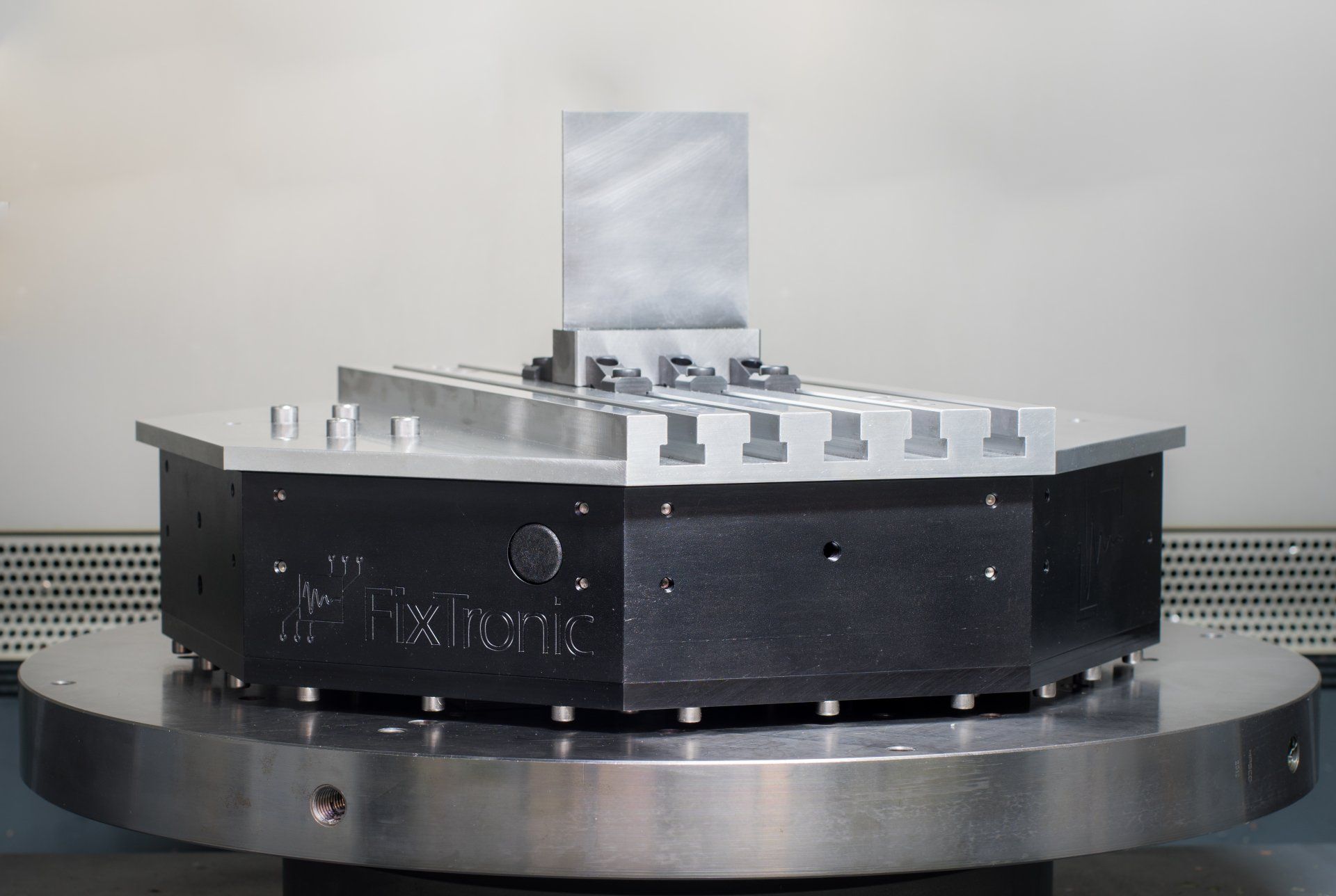

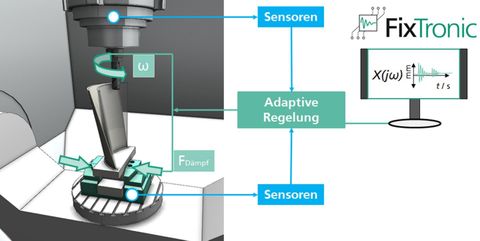

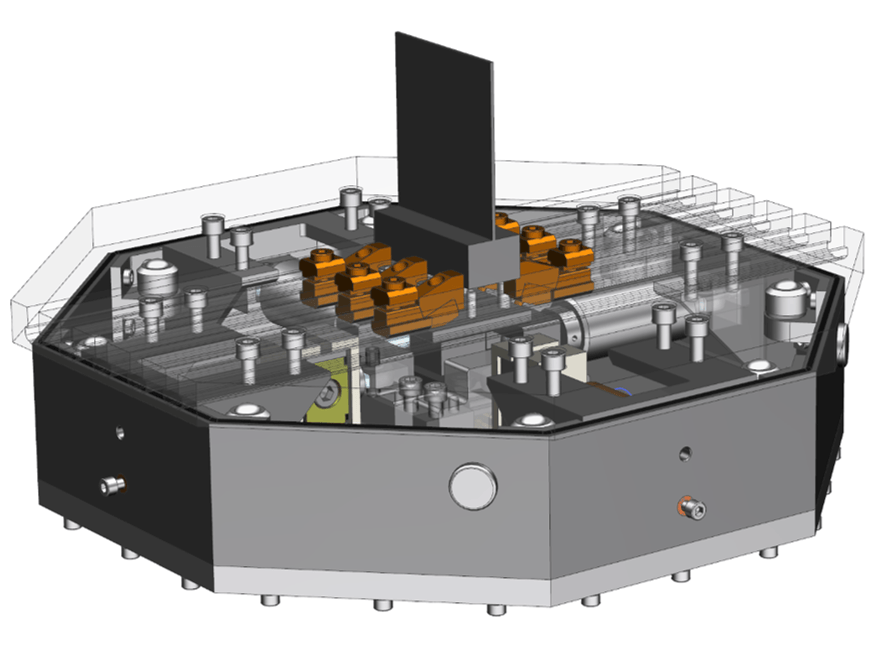

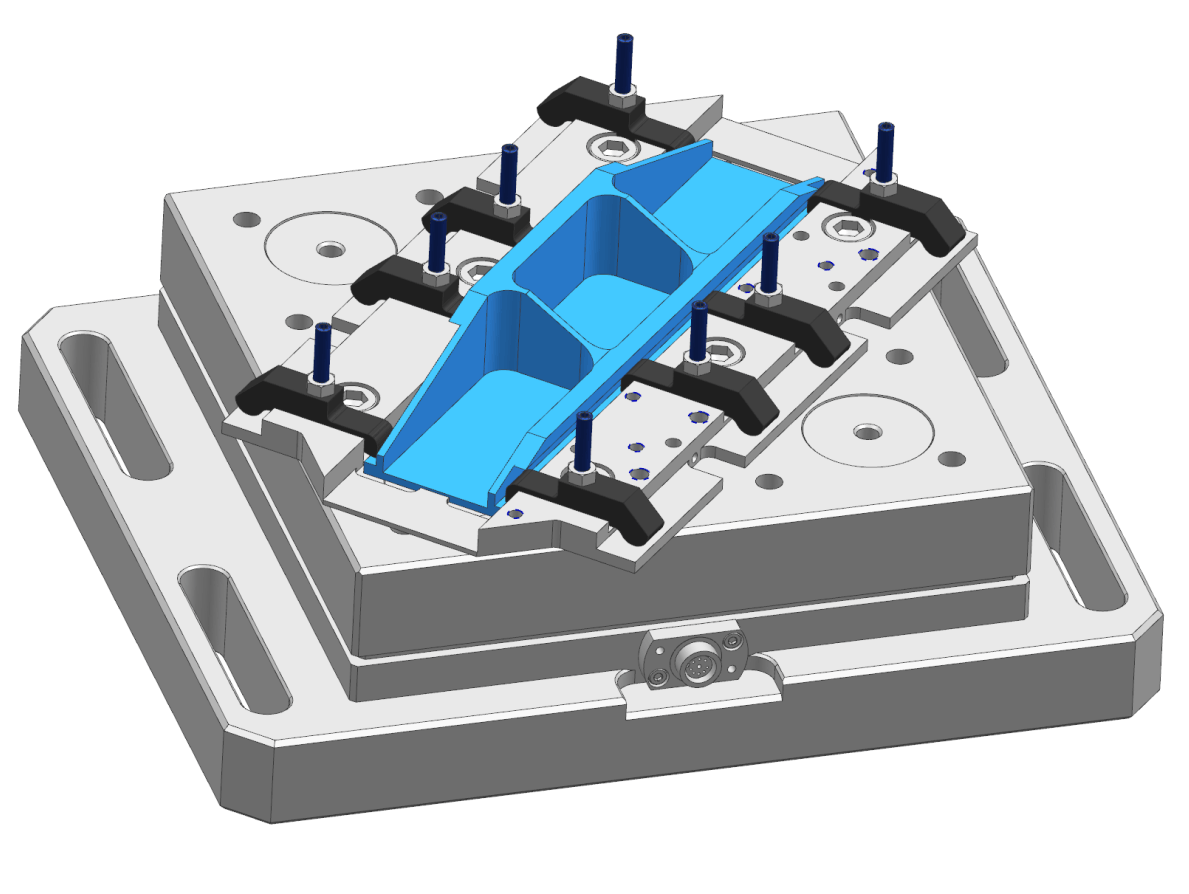

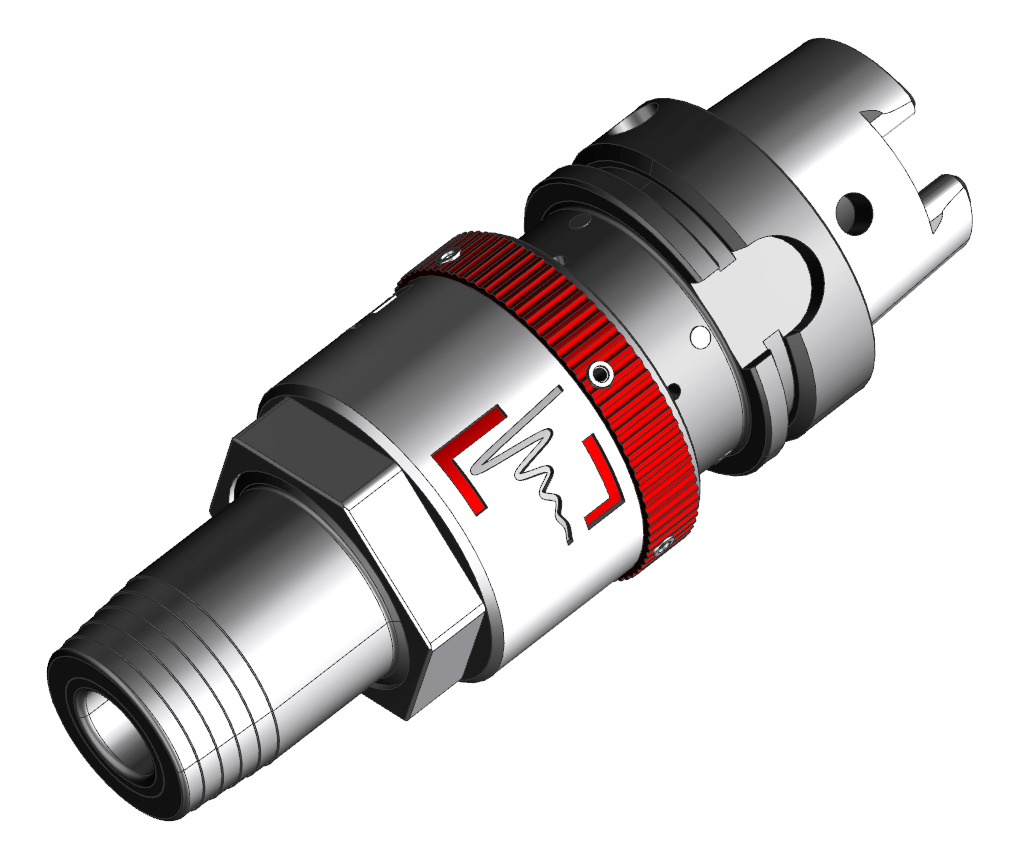

In the FixTronic research project, we are working with our project partners to develop a mechatronic clamping system that minimizes process vibrations and instabilities through active vibration damping: During milling, for example, information about the condition of the workpiece is recorded by sensors in the clamping system and linked to an adaptive control system. Piezo actuators generate a targeted counter-vibration in the workpiece, which significantly reduces the vibrations. In principle, the function of the system is comparable to a noise cancelling headphone.

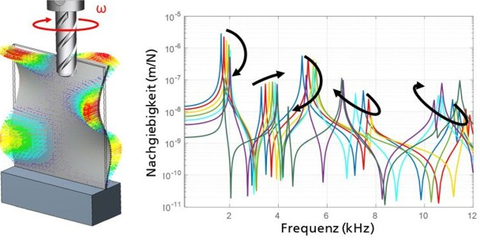

The mechatronic clamping system

The FixTronic mechatronic clamping system enables the use of powerful process parameters while maintaining high quality production results. Thanks to the intelligent adaptive control of the mechatronic system, especially workpieces with long projecting and thin-walled geometry can be clamped in a process-safe manner - thus closing another technical gap in the machining industry 4.0 production. The networking of the clamping system with the machine tool additionally enables effective monitoring of the stability behavior of the workpiece, thus allowing for process-reliable machining with powerful parameters.