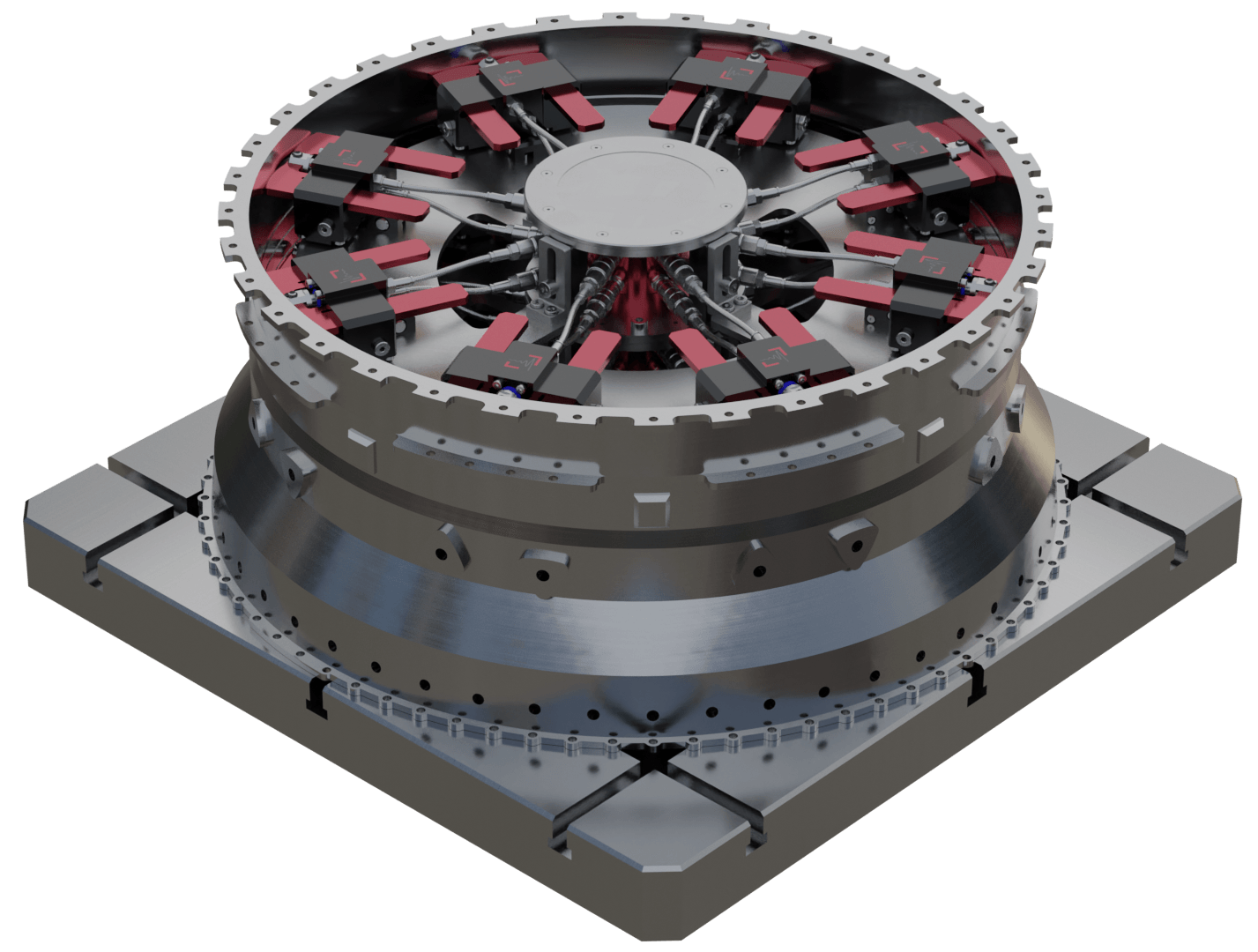

1. Automatic placement

The BLISKER clamping system is automatically retrieved from the tool magazine by the machine.

The BLISKER is then placed on the workpiece by the machine, whereby the spring-loaded clamping elements adapt flexibly to the geometry of the workpiece.

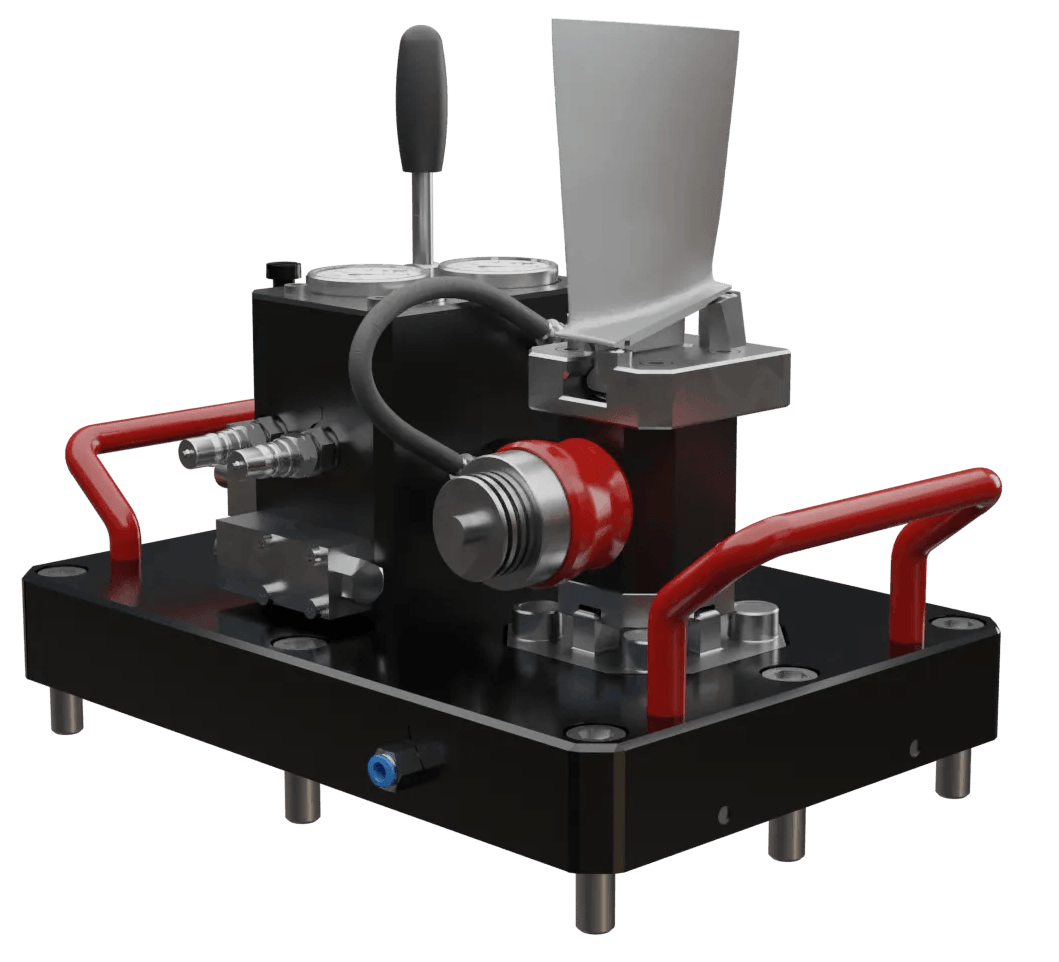

2. Automatic clamping

The BLISKER clamping system is locked by the cooling lubricant from the spindle.

The workpiece is not deformed in this process, as the BLISKER principle only clamps the clamping elements with high forces.

The individual thin-walled geometries of the component are not in the flow of the clamping forces.

3. Machining

After the clamping process, the BLISKER clamping system is separated from the holder and remains on the workpiece. The empty holder is then returned to the tool magazine, the tool is changed into the spindle and machining begins.

The clamping process and the machining can optionally be monitored wirelessly by an integrated sensor in the BLISKER.

Stable workpiece CNC machining

Our patented BLISKER adapts to thin-walled workpieces, stabilizes and minimizes vibrations.

Reduction of rework

The BLISKER improves surface finish and shape accuracy of workpieces, thus reducing rework.

Fully automated clamping device

Our BLISKER clamping system is used fully automated like a normal tool from the tool magazine.