Clamping system for compensation of internal stresses

In the VoKoES research project, we are developing a hydraulic clamping system together with our partners from research and industry that compensates for residual stress-related component distortion from milling processes in order to make machining easier and more economical.

Challenge from industrial production

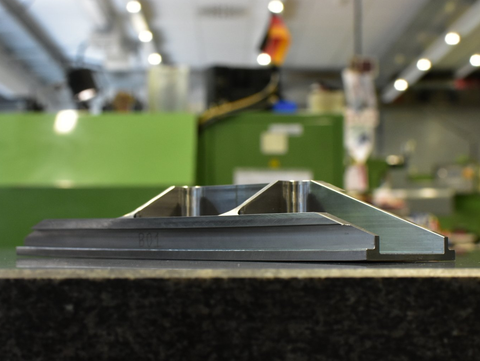

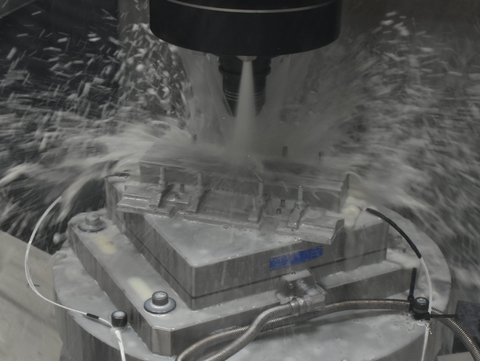

During the production of metal components, material removal causes changes in the material structure and component volume. This causes changes in the shape of the component, which become visible immediately after de-clamping the used fixture.

In manufacturing companies, components at risk of distortion are re-clamped several times in an adapted fixture and manually set up several times. However, this process is time-consuming. Another possibility is to straighten the distorted workpieces after mechanical machining. Here, an attempt is made to bend the workpiece into the desired shape. To reduce or eliminate distortions by straightening is always time-consuming and cost-intensive or not possible at all and then leads to the scrapping of the component.

Solution path in the research project

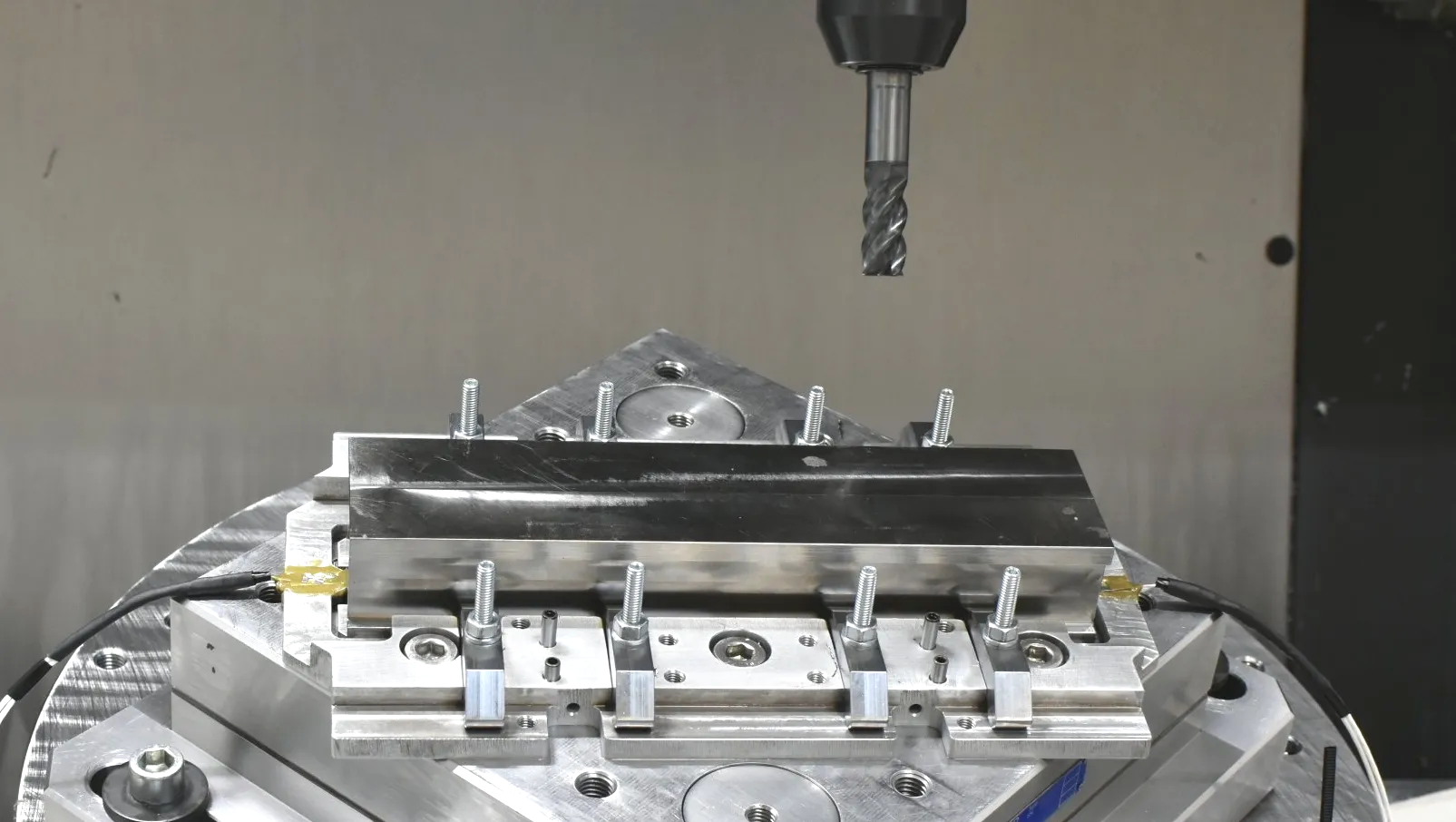

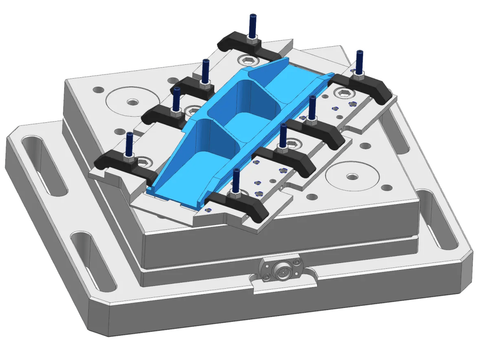

In the VoKoES research project, we are developing a hydraulic clamping system that can easily compensate for component distortion during the machining process of large and thin-walled components. This is of particular interest for geometrically complex, thin-walled components, made of aluminium, titanium or Inconel, which in the aerospace and light-weight construction industries have to be produced mainly by 5-axis machining.

In cooperation with our project partners, VoKoES is also working on simulations for mapping the residual stress states in semi-finished products, algorithms for FEM-simulation of component distortion during 5-axis milling and methods for compensating component distortion during machining based on the previously developed prediction methodology.

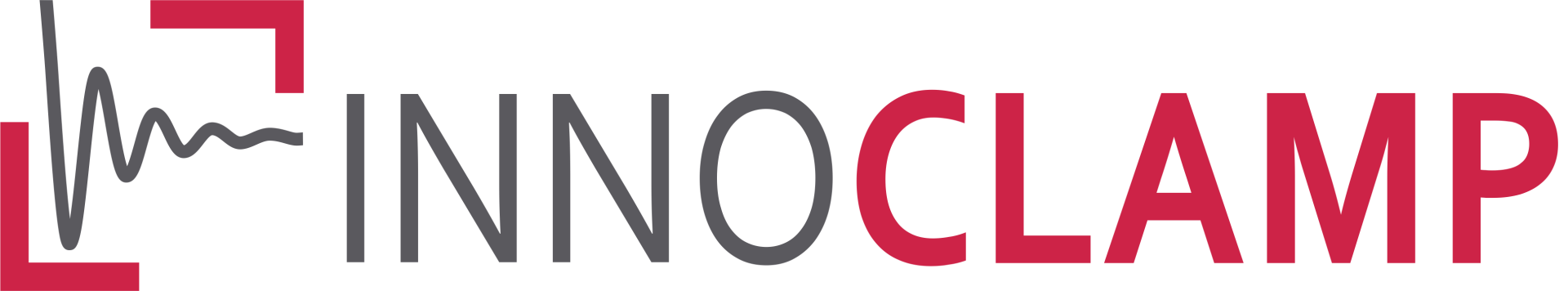

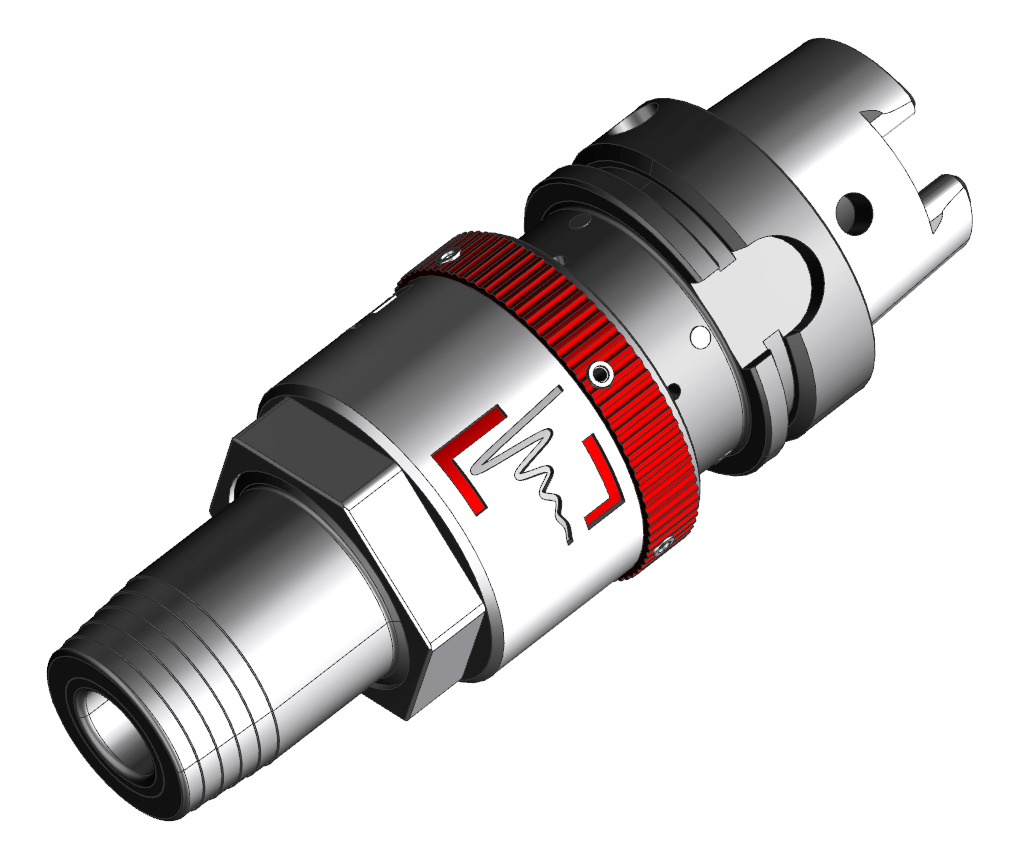

The compensating clamping system

The hydraulic clamping system VoKoES allows the use of powerful process parameters and the ability to easily relax component distortions during the machining process without losing the references of the workpiece and without the need for a new calibration. By using suitable sensor technology, the clamping system can also be used for the detection of distortions occurring in the machining process.

With VoKoES the production of thin-walled, large workpieces becomes more economical, because a more resource-saving and flexible production with less rework and scrap costs due to component distortion is possible.