Clamping complex workpieces during machining time

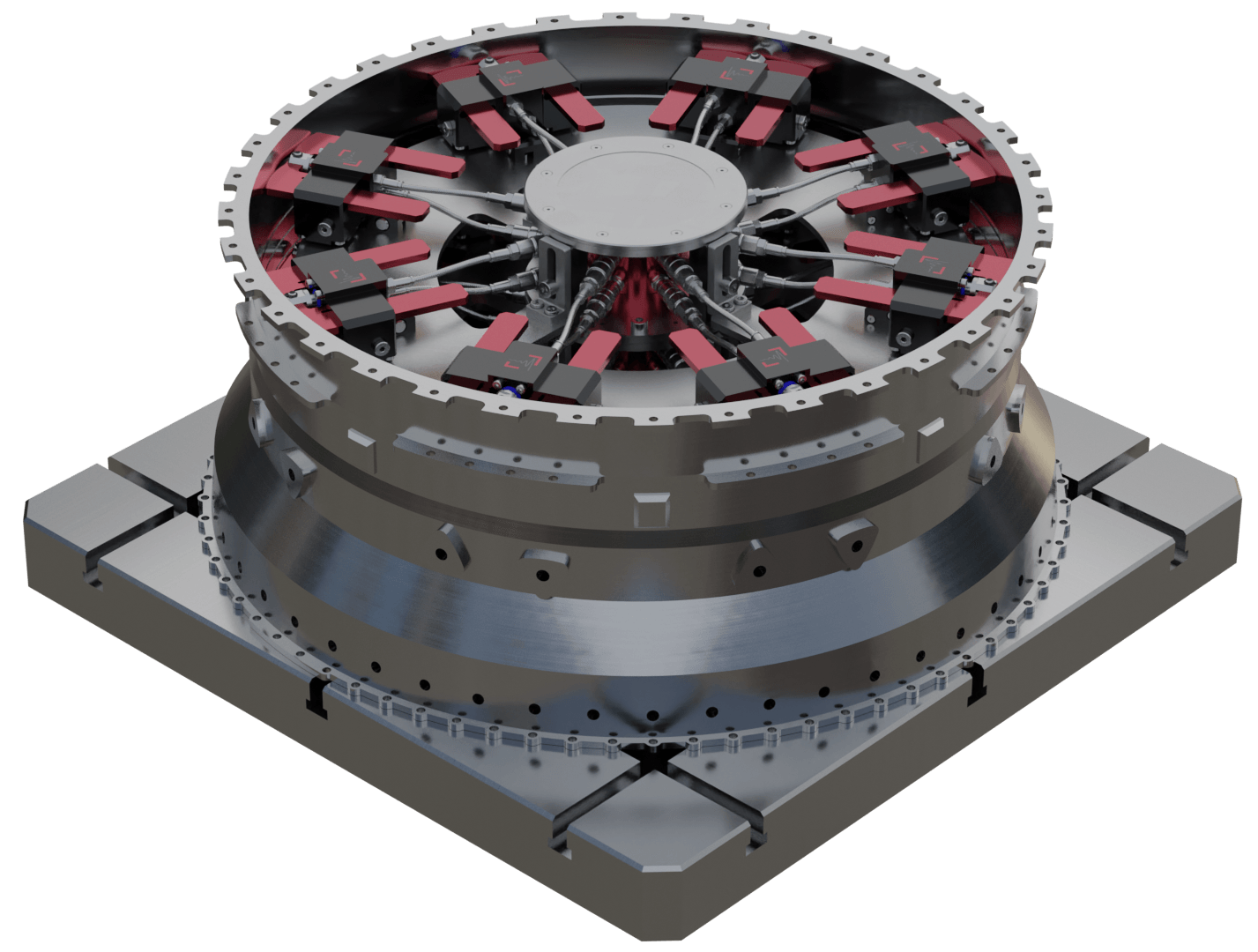

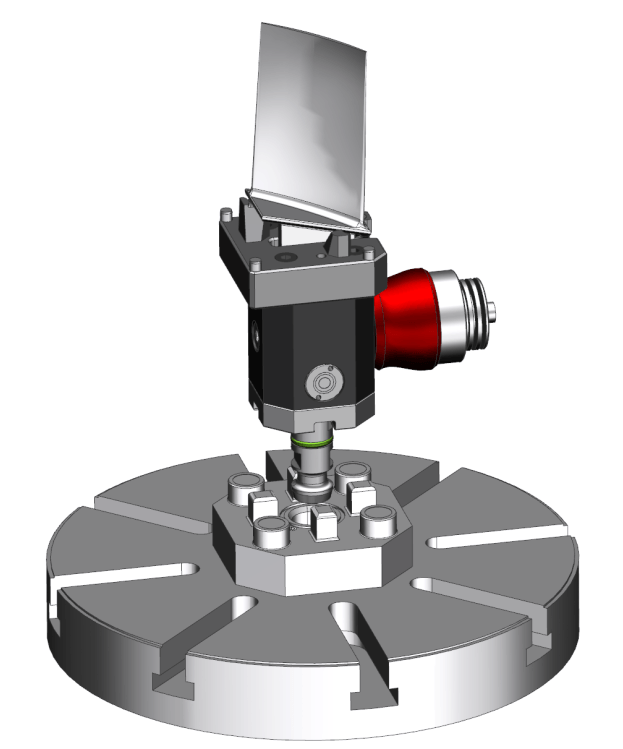

The INNOCARRIER clamping system is a carrier clamping system in which a complex shaped workpiece is aligned and clamped with high precision before machining. The INNOCARRIER is then exchanged by another INNOCARRIER in the machine. In this way, the machine almost never stands still.

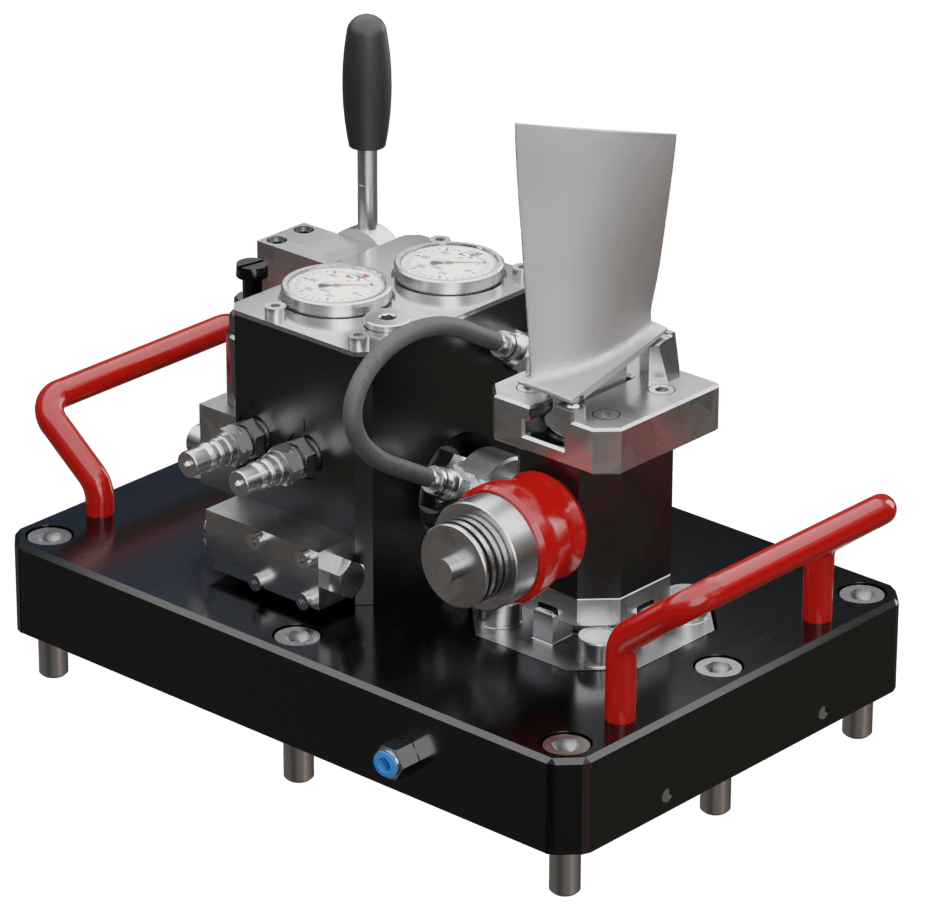

The clamping process is carried out parallel to machine productive time in a hydraulic clamping station next to the machine. After a workpiece has been inserted, the clamping station fills the INNOCARRIER with hydraulic oil in the set pressure range and thus provides the desired clamping force.

Repeatable and accurate workpiece clamping

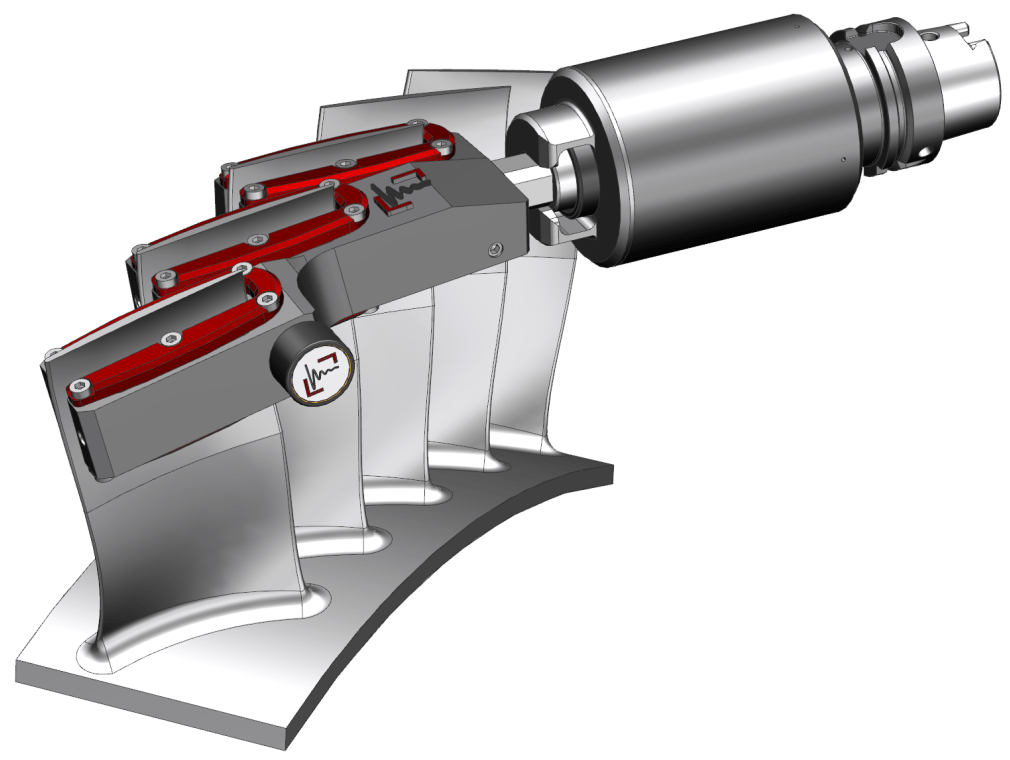

The INNOCARRIER clamping system is changed into the machines via high-precision clamping chucks. During all processing steps the INNOCARRIER remains firmly connected to the workpiece in all processing steps. Therefore, the machining reference from one machine to the next is also retained and a measure in process is not required in each machining step.

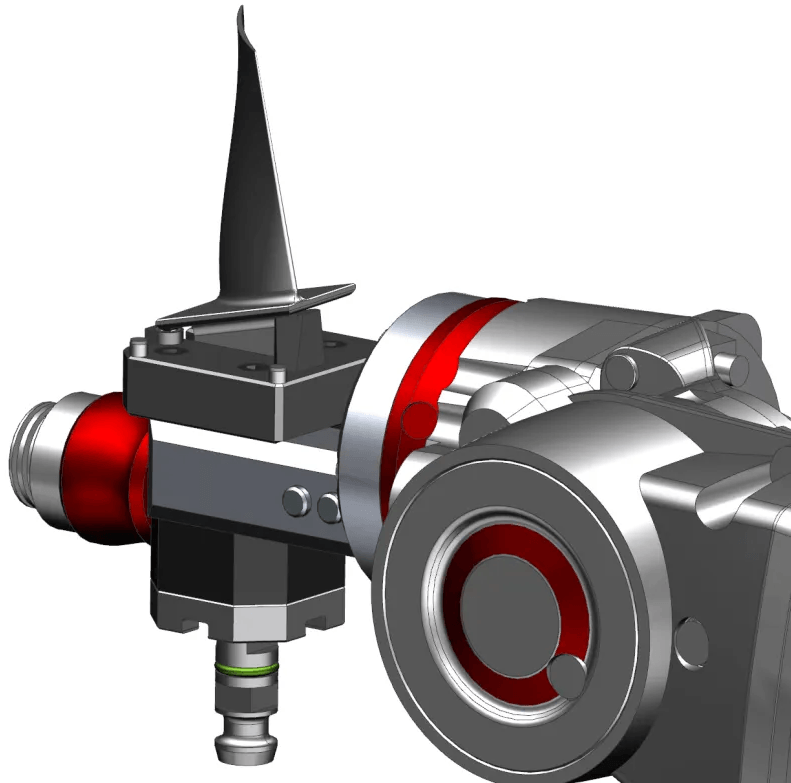

The workpiece is first connected to the carrier within the external hydraulic clamping station, maintaining a repeat accuracy of a few micrometers. The functional elements of the clamping system responsible for the accurate alignment of the workpiece are located on the carrier or in the clamping station. This precision is maintained in the clamped part over the entire process chain.

Automated CNC machining

Fully automated clamping device

The INNOCARRIER is clamped parallel to machine productive time and can be loaded fully automated from magazine.

Highest repeat accuracy

The INNOCARRIER clamps complex shaped

workpieces with highest repeat accuracy within a few micrometers.

Connection of process chains

The INNOCARRIER enables

machining in different machines in the same reference system.